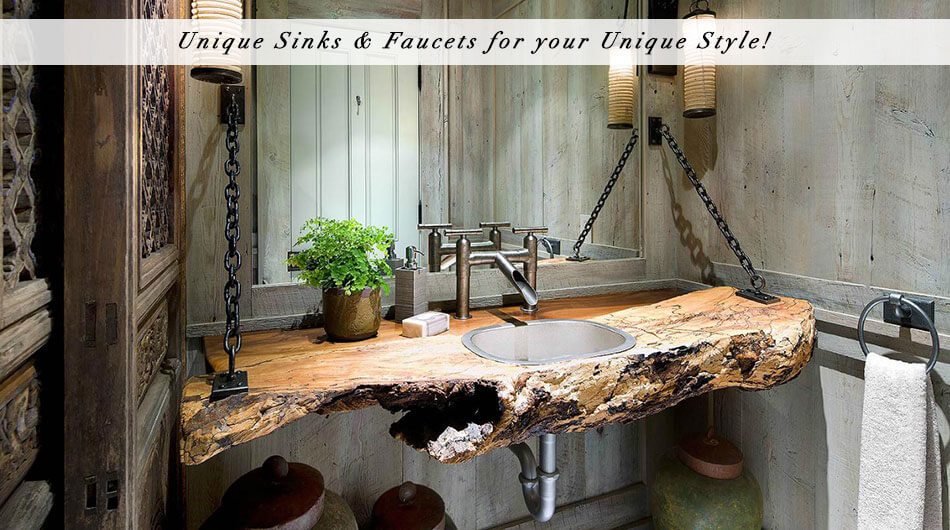

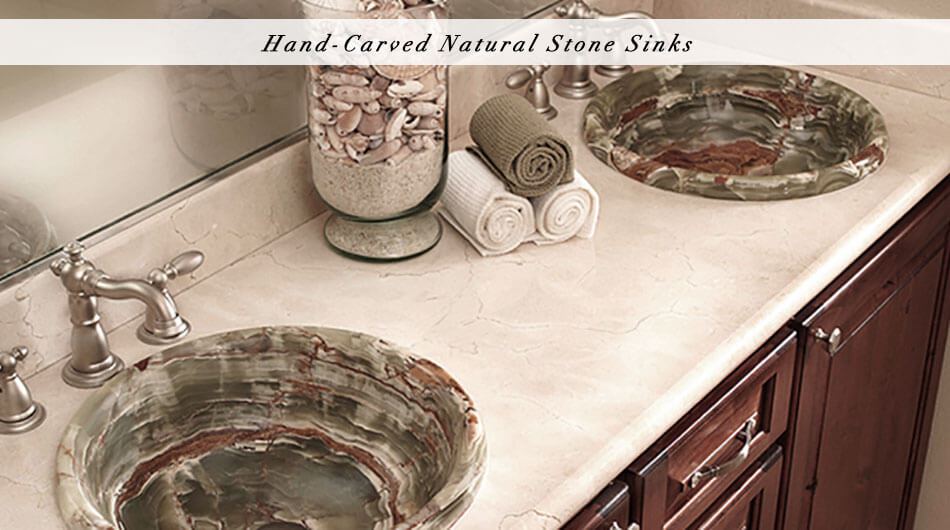

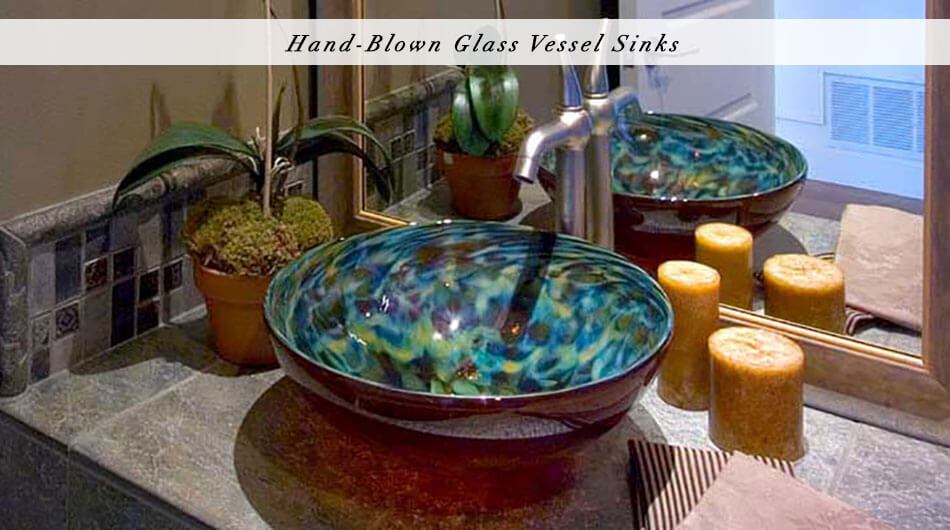

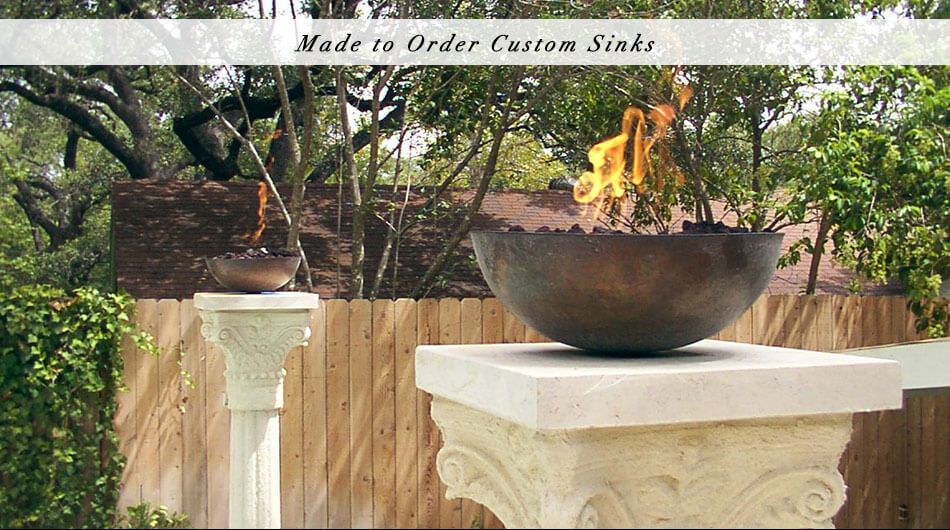

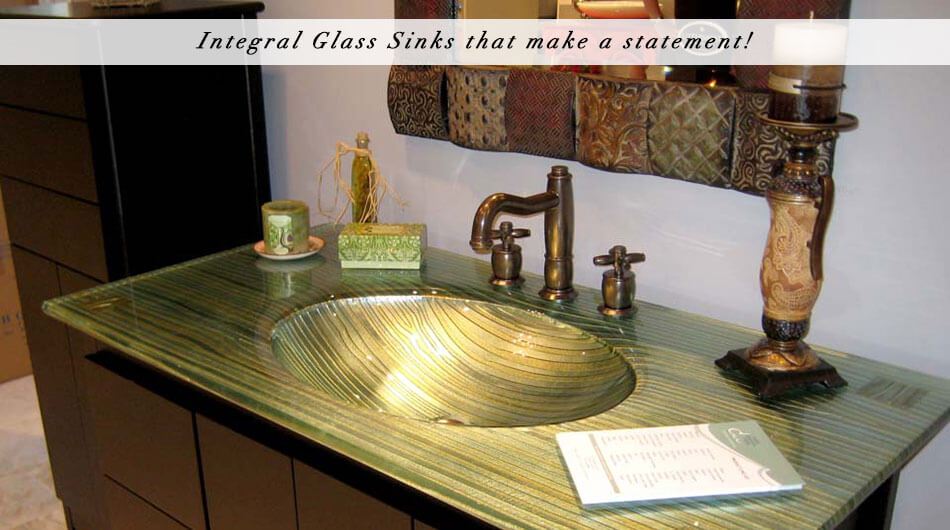

- BATH

Your choice of artisan sinks for the bath

- KITCHEN & BAR

Artisan sinks for the finest kitchens and bars

- FAUCETS

- VANITIES

- ON SALE

- GUIDES & INFO

Our most helpful resources for owning artisan crafted pieces

- SHOP WITH CONFIDENCE

- Eco-Friendly

- Testimonials

Free Shipping on Orders of $100 or more

You have no items in your shopping cart.

Artisan Crafted Home is the premier online store with the largest collection of artisan crafted home furnishings in North America.

Artisan Crafted Lighting features handcrafted lighting fixtures designed with intention and care. Our collection of hand-crafted art lighting artisan resources and custom lighting design services will bring your design to light.